|

|

|

| Ask the Experts | |||||||||||||||

|

|||||||||||||||

|

January 27, 2020 - Updated October 22, 2012 - Originally Posted Un-cleaned PCB Assemblies PottedWe received assembled PCBs that were soldered with a washable flux vs. a no-clean flux. The flux was not removed and the boards were potted with an epoxy based resin and then mounted inside an enclosure. What difficulties do you think we will have? G.M. |

|||||||||||||||

| Expert Panel Responses | |||||||||||||||

|

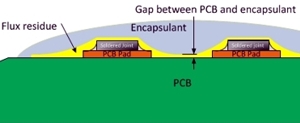

Aqueous-clean solder chemistries must be cleaned to avoid corrosion even in the case of potted PCAs. The presence of flux residue will impede proper adhesion of the potting compound to the PCA thus creating a miniscule gap between the board surface and the potting compound; a potential conduit for corrosion. Corrosion will occur with time especially between any two oppositely charged conductors on the board surface.

Note that corrosion from solder chemistry can occur beneath solder mask on occasion too. Corrosion generation can be confirmed with an abbreviated heat and humidity test and circuit verification or direct observation for corrosive products (may be difficult with presence of potting compound).

President Colab Engineering A thirty year veteran of electronics assembly with major OEMs including Digital Equipment Corp., Compaq and Hewlett-Packard. President of Colab Engineering, LLC; a consulting agency specializing in electronics manufacturing, root-cause analysis and manufacturing improvement. Holder of six U.S. process patents. Authored several sections and chapters on circuit assembly for industry handbooks. Wrote a treatise on laser soldering for Laser Institute of America's LIA Handbook of Laser Materials Processing. Diverse background includes significant stints and contributions in electrochemistry, photovoltaics, silicon crystal growth and laser processing prior to entering the world of PCAs. Member of SMTA. Member of the Technical Journal Committee of the Surface Mount Technology Association.

There are many variables associated with your question. For example, was this "washable flux" a water-based OA type of flux or was it a rosin-based R type of flux? Also, what is the expected reliability level of the components? Does failure of the board risk human life? Or, does failure of the board mean that someone's toaster or hair-dryer will no longer function. There is a high likelihood that these boards will fail, sooner than later, and the decision to scrap the boards needs to be seriously considered. The OA flux is highly acidic and the rosin-based products could lead to much faster than normal dendritic growth and shorts... depends on humidity and temperature and current. If the application is a low reliability application with a product that would pose no risk if it fails, then so be it. All that is at sake is your company's reputation. If you want to ensure the product will meet the designed reliability life and maintain your company's reputation I would either scrap or rework the boards. If it is a system that could risk human-life if it fails, there is no doubt that the boards must be scrapped.

President Chem Logic Rick Perkins is a chemical engineer with more than 33 years of Materials & Processes experience. He has worked with Honeywell Aerospace in high-reliability manufacturing, as well as with several oil-field manufacturing companies. He also has a good understanding of environmental, health, and safety regulations.

The key to answering this question would be to know exactly whatf lux was used. The ionic activity of the flux is what you want to understand. A highly ionic flux may have long term effects of potential corrosion. Most rosin based fluxes are typically inert after soldering, and should not cause a problem. The other concern would be if the epoxy potting adhesion was affected by the flux residue. Are the boards truly encapsulated or not? I would recommend a moisture and insulation resistance test of a sample unit to gain confidence of the assembly.

Product Manager Minco Products Inc Nick has been in the circuit industry since 1985, in technical and management roles. Nick is the Vice Chair of the IPC Flexible Circuits Committee, and Chair of IPC 6013 Flexible Circuits Perfomance Subcommittee. Nick holds a Bachelors Degree in Mechanical Engineering and a Masters Degree in the Management of Technology from the University of Minnesota.

There are two very different possible scenarios here:

If a water-soluble flux was used, the assemblies are not useable in any scenario I can imagine.In the second case, if the flux is relatively benign, like an RMA with "zero halides", and if it has been well-oxidized so that the residue is a hard resin, the outlook may be much better. In fact, some RMA residues can, under good conditions, be as benign asa no-clean. There is another problem, and that is knowing whether the specific flux used will inhibit cure and/or adhesion of the potting compound.This could be tested directly compared to your specified flux.Ask the assembler which flux specifically was used; if it was a water-soluble, do not use the assemblies. If it was rosin-based and a no-halide RMA (not an RA) then:

Process Engineer Astronautics Fritz's career in electronics manufacturing has included diverse engineering roles including PWB fabrication, thick film print & fire, SMT and wave/selective solder process engineering, and electronics materials development and marketing. Fritz's educational background is in mechanical engineering with an emphasis on materials science. Design of Experiments (DoE) techniques have been an area of independent study. Fritz has published over a dozen papers at various industry conferences.

All of the water-soluble fluxes I am familiar with are highly activated. These residues must be removed, and as soon as possible, after the soldering process to prevent the activating acids and/or salt forms from corroding the assembly. By coating over the residues, this essentially has trapped the culprits with no viable way of removing them. However, the corrosion will continue until a probable board failure occurs during service. I'm familiar with these corrosive elements under "conventional" conformal coating, but not the epoxy variety. I assume many of the same failures would occur, though. You can either perform a life cycle test on the board in the same service environment and make a risk assessment at that time. Epoxy is extremely difficult to remove, so that may not be a feasible option. You may end up removing these particular boards from service and clean the residues in the future prior to coating.

Laboratory Mgr. Techspray Pierce Pillon is the Laboratory Manager and lead formulations chemist at Techspray, a division of Illinois Tool Works (ITW) and a leading manufacturer of chemical products for the electronics industry.

In all likelihood, this assembly will suffer multiple failures. First, the coating over OA flux will most likely fail due to delimitation of the coating. Second, OA (water soluble) fluxes among the most aggressive flux types, both before reflow and after. OA flux retains much of its activity after reflow. The flux will remain corrosive and conductive. There are few viable options available once the assemblies have been coated. If coating removal is possible (potting compounds are not normally removed) then the assemblies may be cleaned however the damage has most likely been done. The best solution is to ensure that this does not happen again. Water soluble fluxes MUST be soon after reflow. This is not an option. Other flux types (RMA, No-Clean), should be removed prior to coating.

President Aqueous Technologies Mr. Konrad has been in the electronic assembly equipment industry since 1985. He is founder and CEO of Aqueous Technologies Corporation, a manufacturer of automatic de-fluxing equipment, chemicals, and cleanliness testing systems.

It is possible that you would see corrosion and/or electromigration.

General Manager Trace Laboratories Renee has been with Trace and an IPC member for 16 years. She has managed all military and commercial PB qualification and conformance testing and training, as well as product qualification and testing in the areas of solder pastes, fluxes, solder masks, and conformal coat. She is the chairman of the IPC Testing and the IPC-J-STD-004 Flux Specification Committees and the Vice Chairman of the Assembly and Joining Committee. She has published more than a dozen papers and presented at numerous electronics conferences.

If a water washable flux was used, it is important to wash off completely all ionic residues and normally assess cleanliness prior to potting. Water washable flux residues are designed to be removed completely after soldering. Ionic constituents vary from one formula to another but all having good activity in common. If the water washable residues were completely removed in a water cleaning system and board cleanliness assessed under parts and in any part, it should be fine. It is not recommended to leave uncleaned water washable flux residues in contact with the assembly for any length of time. No-clean fluxes are however designed from the start to be left on without cleaning.

Senior Market Development Engineer Kester Mr. Biocca was a chemist with many years experience in soldering technologies. He presented around the world in matters relating to process optimization and assembly. He was the author of many technical papers delivered globally. Mr. Biocca was a respected mentor in the electronics industry. He passed away in November, 2014.

Interesting condition. I would think it depends upon the initial moisture in the environment prior to potting the product. If the flux was a water soluble flux and was not cleaned off, it could still be active and if moisture was available it could create corrosion products on the surface of the board. You also could generate dendritic growth between conductors if the proper conditions were met. If the board was completely coated with epoxy resin the moisture absorption would be minimal, so the long term risk may be minimal, but corrosion is corrosion and once started who know how it will progress. I would suggest evaluating units from the field to determine if any damage or deterioration occurred on the surface of the board due to material left behind prior to epoxy coating or potting.

Vice President, Technical Director EPTAC Corporation At EPTAC Corporation, Mr. Lambert oversees content of course offerings, IPC Certification programs and provides customers with expert consultation in electronics manufacturing, including RoHS/WEEE and lead free issues. Leo is also the IPC General Chairman for the Assembly/Joining Process Committee.

If the flux was intended to be removed by a wash and was not then the consequences could severe. Many washable fluxes are highly corrosive and MUST be removed. You will have corrosion and failures in the field.

SME Production Technical Excellence Staff Lockheed Martin Subject matter expert in the field of electronics assembly and soldering.

I see a number of potential difficulties that may arise in this instance, but the big unknown will be the behavior of the activators in the flux. If this flux has a significant activation, the chance for corrosion of the metal leads on components is high. This will be compounded by the heat on the boards, entrapped by the potting compound, as heat increases the corrosive effects of the flux residues. In addition, the presence of the flux probably will impair the bonding of the potting compounds on to surface of the boards; at MicroCare we always recommend rigorous cleaning before the application of conformal coatings or potting compounds to ensure quality bonding. On the other hand, if the bonding holds, the potted boards will be protected from mechanical vibration and from other environmental problems, such as moisture, which will mitigate some of the corrosive effects of the flux residues. If these were my boards, I'd base my use/scrap decision upon the application of the product. If they are going into a hi-relelectronics system, I'd scrap the boards and fire the subcontractor for sloppy workmanship. If they're going into a simple, non-critical application with a short product life, I'd probably use them and set aside a bit extra as a warranty reserve.

Vice President Micro Care Mr. Jones is an electronics cleaning and stencil printing specialist. Averaging over one hundred days a year on the road, Mike visits SMT production sites and circuit board repair facilities in every corner of the globe, helping engineers and technicians work through the complex trade-offs today's demanding electronics require.

If the residues that were left onthe PCB are potentially corrosive then they will essentially shorten the working life of the device. Ionic contaminants are typically flux residues or harmful materials left behind after soldering. They can degrade the reliability of the electronic components and assemblies by contributing to current leakage between the circuitry, causing corrosion and promoting dendrite growth. The epoxy resin in this case has essentially encapsulated the residues onto the PCB. The extent of damage will depend on the type and quantity of residues left on the PCB. It is advisable to rework however epoxy resin is never easy to remove. Electrolube have a couple of resin removal products to offer and I would be happy to discuss this with you further if required.

European Technical Support Specialist Electrolube Ltd Jade Bridges is the European Technical Support Specialist for Electrolube. She is responsible for technical support within Europe, offering assistance to customers with product selection, implementation and after sales support across the range of Electrolube products. Her expertise is carried over from her position as R&D Manager for Electrolube, where she was responsible for the new product development and technical support across an array of chemical products for the electronics industry, including conformal coatings, encapsulation resins, thermal management products, contact lubrication and electronic cleaning solutions.

To give an exact answer I would need to know exactly what the flux is.Generally speaking fluxes that are designed to be washed off are higher activity fluxes and are not designated as no clean. They need to be removed for a reason and that reason is that they are potentially still active or conductive after reflow. Corrosion and potential dendrite growth under the potting compound is a potential problem.

European Manager HumiSeal Chris Palin is currently managing European sales and support for HumiSeal Conformal Coatings. His expertise is in test & reliability, solder technology, power die attach and conformal coating.

Reader Comment

If the equipment is battery powered then an additional risk is a greatly reduced battery life resulting from any leakage currents that may occur due to the flux residues.

David Whalley, Loughborough University, UK

I have heard of equipment designed with a battery life of several years that were failing within months or even weeks due to a similar situation. All of these comments are good ones, but to add to David Whalley's comment about batteries on the assembly, don't forget that every capacitor represents some form of energy storage. So even without any battery, you may have some power applied, and it certainly does not take much to promote dendritic growth.

Advanced Engineer/Scientist General Dynamics Richard D. Stadem is an advanced engineer/scientist for General Dynamics and is also a consulting engineer for other companies. He has 38 years of engineering experience having worked for Honeywell, ADC, Pemstar (now Benchmark), Analog Technologies, and General Dynamics.

|

|||||||||||||||

| Submit A Comment | |||||||||||||||

|

Comments are reviewed prior to posting. You must include your full name to have your comments posted. We will not post your email address. |

|

Free Newsletter Subscription

Circuitnet is built for professionals who bear the responsibility of looking ahead, imagining the future, and preparing for it. Insert Your Email Address |

|

|